Georgia Voukia is an architecture student who is currently on Cohort as part of an erasmus placement – we caught up with her about how it’s going so far.

Can you tell us a bit about your background as a maker, your practice and areas of interest?

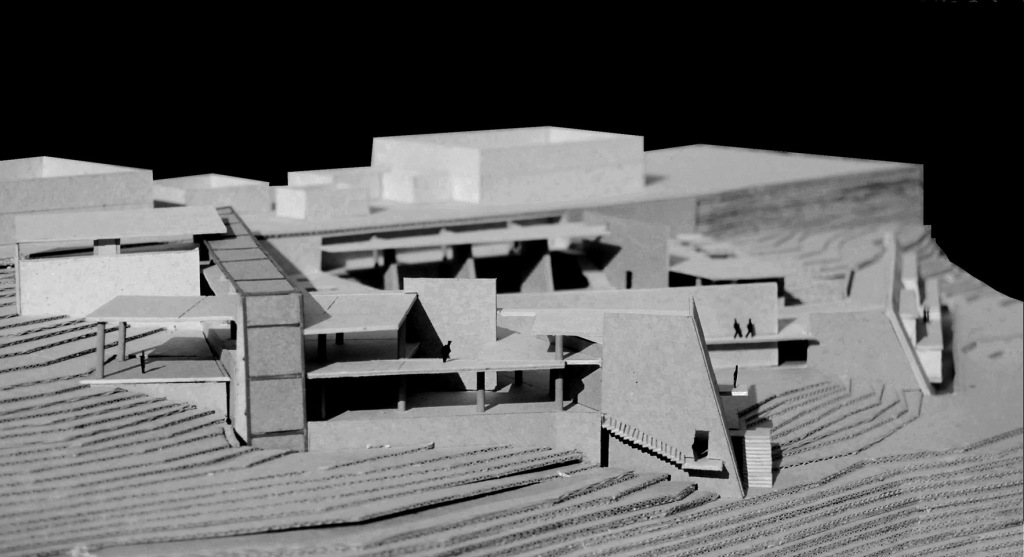

During my architecture studies I became very interested in the model making process so I spent a lot of time practicing on that. By the time I graduated I had already completed a great number of models with various materials like paper, cardboard, stucco, metal, plastics etc, not only for my projects but also models on demand for other teams and collectives.

Having grown up in a family of makers, my interest in these tools and structures happened quite effortlessly.

The next step was my postgraduate programme in design technology for wood and furniture. I chose this course not so much for my interest in furniture design, but my interest in fabrication technology, a knowledge that I can apply to model making and other design projects.

What have you been working on, and what you will be working on, during your time at MR?

Here at Machines Room, I am working on a wide variety of things such as 3d printing with Batch.Works, helping Mark, MR’s technician, with the CNC, and many other fabrication processes that take place here.

Of course I am also working on my Cohort project about parasitic sustainable architecture. This is a project about designing shelter for people who’ve lost their homes because of natural disasters, cases like earthquakes in Italy, fires in the UK, floods in Athens etc. This research aims for a sustainable architecture design with modularity principles, using wood as the main material and adaptability as the main goal. That means that different modular components can be put together to cover the needs of one or more people, of a nuclear or a large family, in a quick and easy installation that provides shelter as soon as possible.

Does having access to the machines, expertise and community at Machines Room influence your work and practice, if so then how?

Access to such a variety of machines and interaction with people with many different areas of expertise and processes is really fascinating. It actually gives me the chance to get out of the box and to combine my studies and my interests in a balanced way.

What are you finding most challenging?

At the same time this wide variety of fabrication processes and areas of expertise is the most challenging thing in this internship. At first you feel somehow bombed with information and new experiences and then it’s time to manage all that, whilst keeping in mind those that help you evolve and move forward.

What has been the highlight of your experience at MR so far?

It is probably too soon to pick one highlight, but I think the people that I’ve met here and seeing how they all work on their own projects but collaborate at the same time within this community is the highlight of the whole experience.

What is next for you after Cohort? Are you planning to continue this stream of work or start a new project?

And finally, the most difficult question is ‘what’s next ?’. I definitely have to go back to Greece to finish my postgraduate programme and reflect on everything that I’ve experienced here in order to make a conclusion.

As far as plans after that, I am currently wavering between experiencing and learning in communities and labs equivalent to Machines Room, or staying in Greece to try and import new things into fabrication in my hometown.

Find out more about Georgia here.